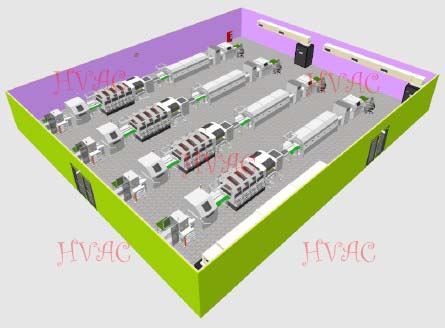

针对SMT车间的空调解决方案,SMT车间的特点为生产工作场所,SMT车间有大量发热设备,SMT车间内生产人员不会太多。根据SMT车间的特点,精密空调选型推荐如下:HIMOD flagship 65U机型。

This is a solution of A/C for a SMT workshop. The characteristic of the SMT workshop is the place of production, and there is a large amount of equipment. Production personnel are not too much. According to the characteristics of the space for the SMT workshop, the selection of model is recommended as HIMOD flagship 65U.

经济效益评估:(Economic Evaluation)

This is a solution of A/C for a SMT workshop. The characteristic of the SMT workshop is the place of production, and there is a large amount of equipment. Production personnel are not too much. According to the characteristics of the space for the SMT workshop, the selection of model is recommended as HIMOD flagship 65U.

经济效益评估:(Economic Evaluation)

- 该SMT车间需安装机房精密空调面积总计800平方米左右,有大量发热设备,对温湿控制及节能有要求,依据实际情况每平米所需制冷量平均按350W计算,总需求的280KW制冷量。

The total area is of about 800 square meters for the SMT workshop, and there is a large amount of heat source, and it requires the temperature and humidity control and energy saving features. Required cooling capacity per square meter on average calculated based on the actual situation according to 350W, the total demand for cooling capacity is of 280KW.

- 要满足该项目280KW的制冷量,需使用HIMOD flagship 65U机组5套装机。

To meet the cooling capacity of 280KW, this project is needed to use five sets of unit (HIMOD flagship 65U).

- 经济效益对比估算:传统空调满足280KW制冷量的输入功率至少为105KW左右,而HIMOD flagship 65U机组5套主机的输入功率合计为65.1KW,主机部分省电38%,全年共计节省电费7.6万元以上。(按1年运行8个月,1月运行30天,1天运行8小时,用电按1元1度计算)

Comparison of economic benefit estimation: the traditional air-conditioning input power (280KW cooling capacity) is at least about 105KW, and the HIMOD flagship 65U input power per set is of 13.2KW. The energy saving is up to 38%. The annual saving is more than 76000 CNY. (According to 8 months per year, 30 days per month, 8 hours per day of operation, electricity by 1 CNY/1 degree calculation)